Attenstion!!!Corrosion resistance of various stainless steels

E-BON

E-BON

2017-10-09 17:03:40

It is a versatile stainless steel, widely used to make equipment and parts that require good overall performance (corrosion resistance and formability). 301 stainless steel shows obvious work hardening during deformation and is used in various occasions requiring higher strength.

302 stainless iron is essentially a higher carbon content of 304 stainless iron varieties, by cold rolling can make it higher strength.

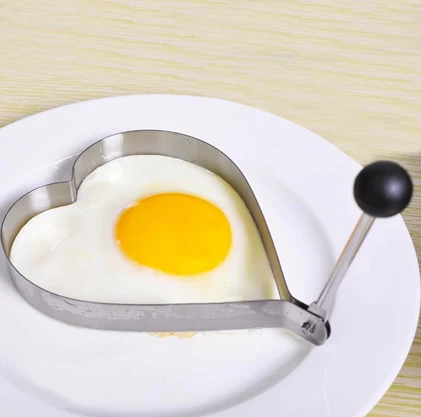

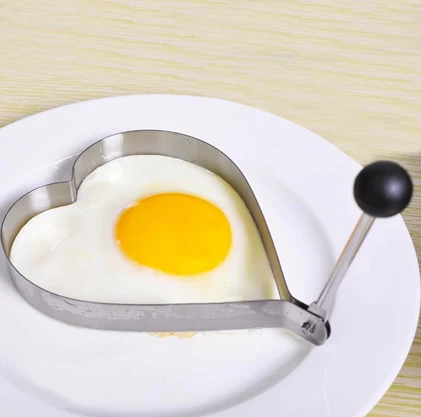

302B is a kind of stainless iron with high content of silicon. It has high oxidation resistance at high temperature. E-BON the stainless steel specialist, China Kitchenware Supplier.

303 and 303Se are respectively containing sulfur and selenium cutting stainless iron, the main requirements for cutting and surface Guanghao high occasions. 303Se stainless iron is also used in the manufacture of parts requiring hot upsetting, because under such conditions, the stainless iron has a good machinability.

304L is a low carbon, 304 stainless iron variety used in welding applications. The lower carbon content minimizes the precipitation in the heat affected zone near the weld, while the precipitation of the carbide may lead to intergranular corrosion (bonding erosion) of the stainless steel in certain environments.

304N is a nitrogen free stainless iron, plus nitrogen in order to increase the strength of iron. E-BON the most excellent stainless steel company, which provide you with Cocktail Muddler China.

304N is a nitrogen free stainless iron, plus nitrogen in order to increase the strength of iron. E-BON the most excellent stainless steel company, which provide you with Cocktail Muddler China.

305 and 384 stainless iron contain higher nickel, its work hardening rate is low, suitable for cold forming requirements of a variety of occasions.

308 stainless iron is used to make electrodes.

309, 310, 314 and 330 stainless steel has higher content of nickel and chromium, in order to improve the oxidation resistance and creep strength of iron at high temperature. While 30S5 and 310S are 309 and 310 stainless iron varieties, the difference is only lower carbon content, in order to minimize the precipitation of carbides near the weld. 330 stainless steel has a high resistance to carburizing and thermal shock resistance.

The 316 and 317 types of stainless iron contain aluminum, so they are much better than 304 stainless steels in the marine and chemical industries. Among them, 316 types of stainless steel by variants, including low carbon stainless steel, iron, 316L, nitrogen high-strength stainless steel 316N, as well as a higher amount of sulfur free cutting stainless iron 316F.

The 316 and 317 types of stainless iron contain aluminum, so they are much better than 304 stainless steels in the marine and chemical industries. Among them, 316 types of stainless steel by variants, including low carbon stainless steel, iron, 316L, nitrogen high-strength stainless steel 316N, as well as a higher amount of sulfur free cutting stainless iron 316F.

321, 347 and 348 are stainless steels, which are stabilized by titanium, niobium, tantalum and niobium, and are suitable for welding at high temperatures. 348 is a kind of stainless iron which is suitable for the nuclear power industry. It has some restrictions on the amount of tantalum and cobalt.

302 stainless iron is essentially a higher carbon content of 304 stainless iron varieties, by cold rolling can make it higher strength.

302B is a kind of stainless iron with high content of silicon. It has high oxidation resistance at high temperature. E-BON the stainless steel specialist, China Kitchenware Supplier.

303 and 303Se are respectively containing sulfur and selenium cutting stainless iron, the main requirements for cutting and surface Guanghao high occasions. 303Se stainless iron is also used in the manufacture of parts requiring hot upsetting, because under such conditions, the stainless iron has a good machinability.

304L is a low carbon, 304 stainless iron variety used in welding applications. The lower carbon content minimizes the precipitation in the heat affected zone near the weld, while the precipitation of the carbide may lead to intergranular corrosion (bonding erosion) of the stainless steel in certain environments.

305 and 384 stainless iron contain higher nickel, its work hardening rate is low, suitable for cold forming requirements of a variety of occasions.

308 stainless iron is used to make electrodes.

309, 310, 314 and 330 stainless steel has higher content of nickel and chromium, in order to improve the oxidation resistance and creep strength of iron at high temperature. While 30S5 and 310S are 309 and 310 stainless iron varieties, the difference is only lower carbon content, in order to minimize the precipitation of carbides near the weld. 330 stainless steel has a high resistance to carburizing and thermal shock resistance.

321, 347 and 348 are stainless steels, which are stabilized by titanium, niobium, tantalum and niobium, and are suitable for welding at high temperatures. 348 is a kind of stainless iron which is suitable for the nuclear power industry. It has some restrictions on the amount of tantalum and cobalt.

If you want to get more information about E-BON, you can click Stainless Steel Milk Cup wholesales china.